The Main Principles Of Steel Fabrication Apprenticeship

Wiki Article

Steel Fabrication Meaning for Dummies

Table of ContentsThe 9-Second Trick For Steel Fabrication MeaningThe Single Strategy To Use For Steel Fabrication And Welding9 Simple Techniques For Fabrication Steel ChartThe Best Strategy To Use For Fabrication Steel Chart

Melt tables are CNC (computer-operated) cutting torches, normally powered by natural gas., are additionally usual. Plate steel is loaded on the table as well as the components are cut out as set.

In this very specialized work, warm is selectively put on the steel in a slow-moving, linear sweep, creating the steel to agreement towards the move as it cools down. A very experienced welder can eliminate considerable warpage in this manner. Steel weldments are occasionally annealed in a low-temperature stove to relieve recurring anxieties.

Basically, fabrication is a vital step in creating any kind of kind of finished metal part or framework. Steel fabricators generally work in either device shops or marked fabrication shops that focus on everything from metal prep work to construction. Not as common as the metal fabrication kinds that we'll discuss in this piece, blacksmiths, boilermakers, and also ironworkers have actually likewise traditionally been taken into consideration steel fabricators.

Rumored Buzz on Steel Fabrication Process

Unlike architectural steel manufacture, which we'll obtain to in the next area, industrial metal parts are normally made use of as enhances to each other. Structural Metal Fabrication High-strength structural steel is just one of the most preferred products used in the building and construction area today, whether the project is industrial, commercial, or property in nature.

If you have an industrial, architectural, or commercial steel construction project that needs a personalized touch, please call us today. Chances are, we'll more than happy to state, "Yes, we can do that!".

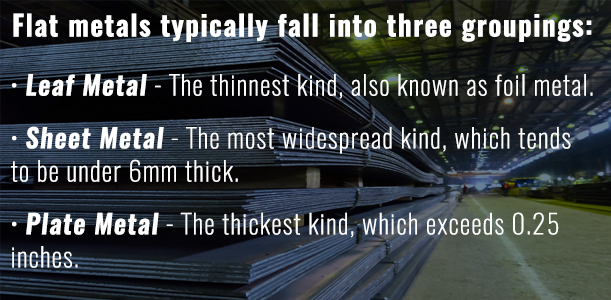

The process starts with sheet steel around a quarter of an inch thick or less. At this thickness, the steel is flexible enough to think different shapes.

What Does Steel Fabrication Near Me Do?

Human beings have been extracting and also machining metal for the past 10 centuries, as confirmed by a copper pendant excavators found in north Iraq that goes back to regarding 9,000 BCE. Manufacture stores as we recognize them today started to exist around the Industrial Change, when sheet metal was in much higher demand than before.Steel manufacture on a wide scale was required to create systems of railroads, telegraph lines, tools, devices, printing presses and also other applies that have actually been so important in our history. All of these advancements depend on maker shops carrying out joints, cuts, bends and creating procedures, just as is done today.

With the onset of the 20th century, metal construction has actually presumed an even larger duty in our lives. We currently perform machining on grand ranges, ranging from little, family-run operations to huge production plants employing thousands of individuals. While steel construction has existed in some form for millennia, the methods and also modern technology have actually evolved substantially with time.

Some of one of the most considerable kinds of steel manufacture modern technology that are currently at the forefront of the manufacture process include: Computer-aided style (CAD) software plays a considerable role in the design of steel construction tasks. Engineers make use of CAD software to establish layouts, which can then be utilized by my link a manufacture business in the fabrication procedure.

The smart Trick of Steel Fabrication And Welding That Nobody is Discussing

These methods are beneficial for a series of different job and also product kinds. These technologies are anticipated to expand in the coming years, specifically as producers press for better adaptability in their tools. There are various procedures associated with steel fabrication. The details combination of metal or stainless-steel manufacture processes will vary with the geometry of the part, the kind of usage it will certainly get and also what it is constructed from.This is what transforms the sheet metal right into an item of the required size and also form. Today, waterjet and also laser cutting make up the primary innovations available. A die creates a mold, and the maker pours liquified metal right into it. This metal cools as well as transforms solid, and also the part stays after removing the die.

Turrets punch pre-designed patterns right into the metal, either for ornamental objectives or utility. A milling system burns out perforations right into the metal, which, due to the nature of the maker, can be non-circular.

Precious steels, such steel fabrication bibra lake as silver and gold, tend to be available in smaller cable, sheet or bar kinds because of their worth. Many metals can also go through a majority of construction processes, though restrictions exist relying on the gentleness, pliability and also density of the steel. The rigidness of steel will impact the kinds of procedures as well as quantity of power needed for steel manufacture, meaning the processes will certainly look different than it would for fabricating a more pliable steel like custom steel fabrication light weight aluminum.

Report this wiki page